EJA438E

EJA438E Diaphragm Sealed Gauge Pressure Transmitter

------Product introduction------------------------------------------------------------------------------------------------------

EJA438E diaphragm sealed pressure transmitter adopts monocrystal silicon resonant sensor technology, which is suitable for measuring the pressure and liquid level of high and low temperature, high vacuum, high viscosity and easy crystallization medium, with rapid response, remote setting, self-diagnosis and other functions.

EJA438E Standard features include:

Transmitter body section

-D .............................

-J .............................

-F .............................

-G.............................

-Q.............................

4 to 20 mA DC with digital communication (BRAIN protocol)

4 to 20 mA DC with digital communication (HART 5/HART 7 protocol)*1

Digital communication (FOUNDATION Fieldbus protocol, refer to

GS 01C31T02-01EN)

Digital communication (PROFIBUS PA protocol, refer to

GS 01C31T04-01EN)

Low Power, 1 to 5 V DC with digital communication (HART 7 protocol)*8

A............................

B............................

0.06 to 3.5 MPa (8.6 to 500 psi)

0.46 to 16 MPa (67 to 2300 psi)*2

J....................

G....................

C....................

B7 carbon steel

316L SST

660 SST

1...............

3...............

2...............

Cast aluminum alloy

Cast aluminum alloy with corrosion resistance properties*3

ASTM CF-8M stainless steel*4

0............

2............

4............

5............

7............

9............

A............

C............

D............

G 1/2 female, one electrical connection without blind plugs

1/2 NPT female, two electrical connections without blind plugs

M20 female, two electrical connections without blind plugs

G 1/2 female, two electrical connections with a blind plug *5

1/2 NPT female, two electrical connections with a blind plug *5

M20 female, two electrical connections with a blind plug *5

G1/2 female, two electrical connections and a 316 SST blind plug

1/2 NPT female, two electrical connections and a 316 SST blind plug

M20 female, two electrical connections and a 316 SST blind plug

D.........

E.........

N.........

Digital indicator*6

Digital indicator with the range setting switch (push button)*7

None

B......

J......

N......

304 SST 2-inch pipe mounting, flat type (for horizontal piping)

316 SST 2-inch pipe mounting, flat type (for horizontal piping)

None

J1......................

J2......................

J4......................

J6......................

A1......................

A2......................

A4......................

D2......................

D4......................

D5......................

P1......................

P2......................

P4......................

JIS 10K

JIS 20K

JIS 40K

JIS 63K

ANSI class 150

ANSI class 300

ANSI class 600

DIN PN10/16

DIN PN25/40

DIN PN64

JPI class 150

JPI class 300

JPI class 600

Process connection size

(Process flange size)

3.....................

2.....................

3-inch (80 mm)

2-inch (50 mm)

A...................

B...................

C...................

JIS S25C

304 SST *11

316 SST *11

1.................

2.................

Serration (for ANSI flange with wetted parts material SW only)

Flat (no serration)

SW .............

HW.............

TW .............

UW.............

[Diaphragm] [Others]

316L SST 316L SST

Hastelloy C-276*9# Hastelloy C-276*9#

Tantalum *7 Tantalum *7 Titanium Titanium

0.............

A.............

B.............

[Ring] [Vent/Drain plugs] [Material]

None — —

Straight type R 1/4 connections*8 316 SST #

Straight type 1/4 NPT connections 316 SST #

Fill fluid

-A ........

-B ........

-C ........

-D ........

-E ........

-1 ........

-2 ........

-4 ........

[Process temperature] [Ambient temperature]

For general use (silicone oil)*3

–10 to 250°C –10 to 60°C

For general use (silicone oil)

–30 to 180°C –15 to 60°C

For high temperature use (silicone oil)*4 *7

10 to 310°C 10 to 60°C

For oil-prohibited use (fluorinated oil)*5

–20 to 120°C –10 to 60°C

For low temperature use (ethylene glycol)

–50 to 100°C –40 to 60°C

High temp. and high vacuum use (Silicone oil)*3*12

–10 to 250°C –10 to 60°C(50°C)*13

High temp. and high vacuum use (Silicone oil) *4*7*12

10 to 310°C 10 to 60°C(50°C)*13

High vacuum use (Silicone oil) *12

–10 to 100°C –10 to 60°C(50°C)*13

1...

2...

3...

4...

5...

1m 6 . . . . . . . . . 6 m

2m 7 . . . . . . . . . 7 m

3m 8 . . . . . . . . . 8 m

4m 9 . . . . . . . . . 9 m

5m A . . . . . . . . . 10 m

Model

Suffix Codes

Description

EJA438E

Diaphragm sealed gauge pressure transmitter

Output signal

Measurement

span (capsule)

─

S.........................

Always S

─

C.........................

Always S

Coverflange bolts and nuts

material

Installation

-9 ................

Horizontal piping type and left side high pressure

Amplifier housing

Electrical connection

Integral indicator

Mounting bracket

Diaphragm seal section

Continued on diaphragm seal section (II)

Diaphragm seal section (Flush type)

------There are more flanges to choose from, if you need, please contact our company

Model

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter body section (I)

Process connection style

-W.........................

Flush type

Flange rating

Flange material

Gasket contact surface*1

Wetted parts material*10

Flushing connection ring*2

Extension

0...........

None

Capillary connection

A.......

Side of diaphragm seal unit

─

2.....

Always 2

Capillary length*6

Option codes

/ Optional specification

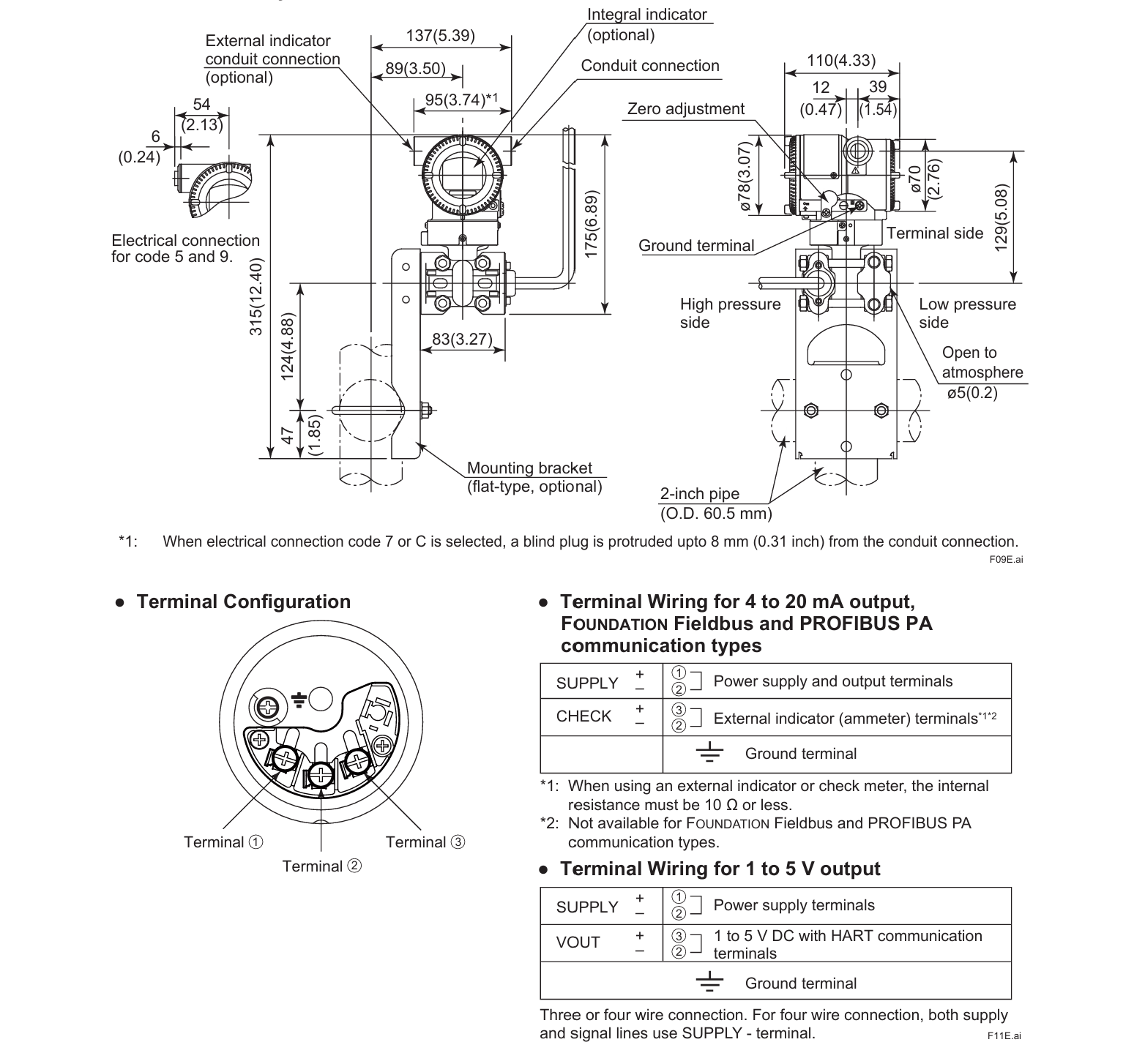

DIMENSIONS

------SERVICE--------------------------------------------------------------------------------------------------------------------------------------------------------

Introduction of Xi 'an Lilu Trading Co., LTD

Xi 'an Lilu Trading Co., Ltd. is a professional import and export focus on transmitter, flow meter, positioner instrument industry provider. We have a huge advantage in the following brand ROSEMOUNT, YOKOGAWA, HONEYWELL, SMC, IMI NORGREN, ABB, ENDRESS + HAUSER, FISHER, YTC, AZBIL, SIEMENS, and some European brands.

We look forward to your inquiry and hope that we can start the best cooperation.

The founding of the company adheres to the service tenet of integrity-based quality survival reputation first, customer-oriented quality as the lifeblood of the enterprise, integrity-centered, so that the enterprise, to provide customers with quality products and thoughtful service, I believe you can find the products you need in the company.